A “puzzle piece” to perfect the service quality

The aircraft air conditioning system, unlike the ones at home or in cars, is a pivotal aircraft component consisting of complicated mechanics. The airflow is taken from the engine compressor and then pulled into the cabin for cooling and maintaining air pressure. Such is the system’s basic working principle.

Maintenance of the aircraft’s air conditioning system is vital as all of its components are interdependent and connected to each other. Should there be any issue with one part of the system (dust, damage, etc.), it will impact the whole system – reducing longevity and increasing the risk of dangerous incidents, operational costs, and power consumption.

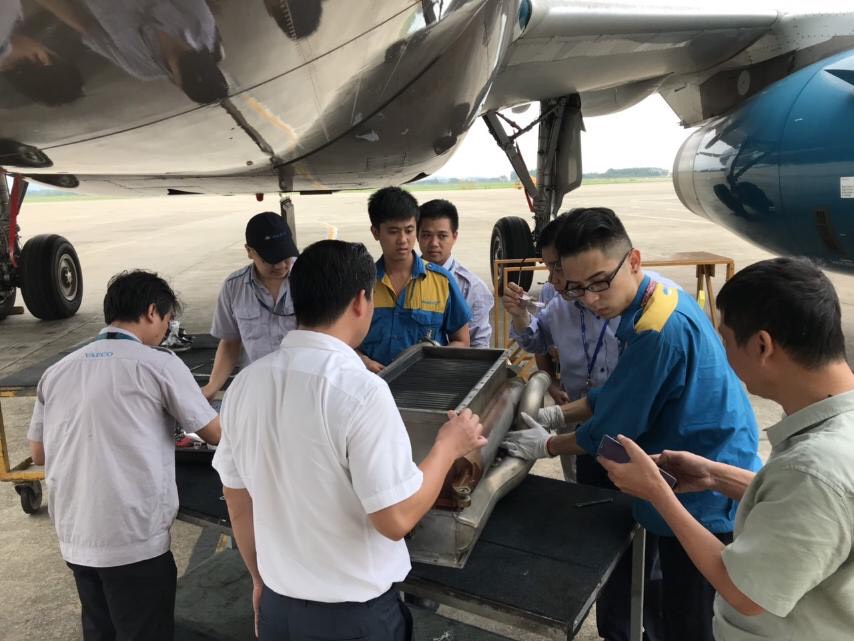

VEACO technicians maintain the aircraft air conditioning system following the direct instruction of the company leadership. (Cre: VAECO).

The maintenance works for the aircraft air conditioning system are carried out as per the maintenance program instructed by the manufacturers. The main/primary heat exchanger, condenser, re-heater, ozone generator, etc., are separated and brought for periodical maintenance checks and cleaning after 9,000-18,000 hours of operation. The maintenance is in line with the above-mentioned program, thus enabling the system to operate stably with high cooling efficiency and ensuring the durability of the system.

Quality is the ultimate goal

As Vietnam is in such a hot, humid, and dusty environment, the aircraft air conditioning system is forced to work continuously to an extent that may shorten the expected lifespan of the system’s components. Some frequently met problems are low cooling efficiency, broken or sub-effective parts prior to inspection. In addition, the maintenance of the air conditioning system also faces many obstacles, one of which is limited spare parts for replacement components.

The most frequently encountered problem is simply dust getting caught inside of the air conditioning system, significantly hampering its effectiveness. Over time, the visible symptoms of this are reduced capacity and prolonged cooling time. Additionally, dust getting caught in the system can hugely affect air filtration. In some cases, it could facilitate bacterial growth, thereby negatively impacting the health of passengers and flight crews if it’s left unchecked for long periods.

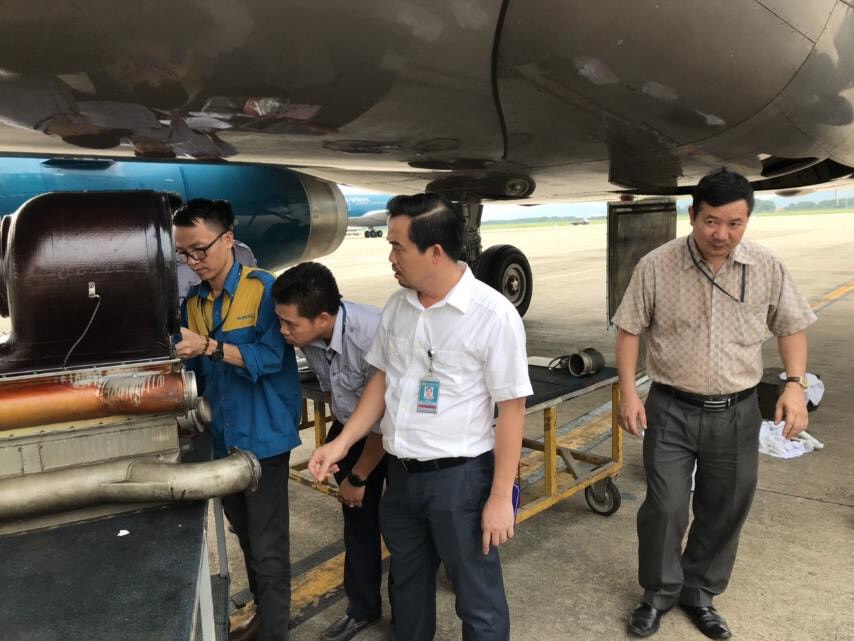

To increase the maintenance’s effectiveness and the system’s life span, VNA always cleans the heat exchanger and regularly checks for air leaks. Recently, VNA has been cleaning the heat exchanger, checking for air leaks, and planning to change parts that are intensively used to prepare the air conditioning systems for the upcoming summer peak. In addition to this preparation, in 2020, VNA has also planned to research and work with the manufacturers to optimize the maintenance and foster innovations that will extend the system’s longevity.

VNA always cleans the heat exchanger and checks for air leaks on a regular basis. (Cre: VEACO).

With the pride of being the national flag carrier, VNA – on its journey to reach further and walk side by side with the world’s five-star airlines – is constantly improving to ensure safety and elevate passenger service quality from even the smallest details.

Nguyen Mai Huong-COMM